The latest development in Cotton Incorporated software program is made to facilitate moving USDA HVI® information electronically between merchants and mills. Cotton Communicator pc software, that will change QRNet32™ pc software, supports a standard electronic data interchange (EDI) document platforms.

The latest development in Cotton Incorporated software program is made to facilitate moving USDA HVI® information electronically between merchants and mills. Cotton Communicator pc software, that will change QRNet32™ pc software, supports a standard electronic data interchange (EDI) document platforms.

Cotton Communicator computer software makes it possible for a user to generate and handle both 856 (Notice of Loading) and 863 (endorsement listing) papers relative to the American National Standards Institute (ANSI). While Cotton Communicator software is built to operate as a standalone package, it can be incorporated with Cotton control program™ (CMS) pc software.

Kirk Andrews, connect Director of Program developing at Cotton Incorporated, defines Cotton Communicator pc software as "easier to utilize, less heavy body weight, plus flexible" than QRNet32 software. This new program, with its streamlined focus on EDI documents, can run using both desktop or laptops in a network environment and may be scaled in relation to the dimensions of business.

A unique effort is under way at Cotton Incorporated to boost the standing of cotton inside women's wear marketplace. Corporate approach and system Metrics is working with Finishing analysis to spotlight increasing the number of cotton fiber in females's clothing by improving the wear while reducing the needed proper care of cotton fiber fabrics.

The 2010 Cotton Incorporated Retail Monitor™ survey*, which is managed by Corporate Strategy and plan Metrics, unveiled that 68 % of females's clothes includes cotton fiber. In comparison, 85 per cent of males's clothing is manufactured out of cotton fiber.

While 75 per cent of males's clothes is 100-percent cotton, just 40 per cent of women's clothes is perhaps all cotton. However, 60 percent of women's clothes includes a cotton combination. The study helped Cotton Incorporated to acknowledge a seasonal variability in the level of cotton fiber in women's clothes, including a higher content of almost 75 percent during the summer use to a reduced content of 60 percent in cold temperatures wear.

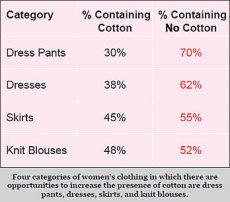

The outcomes of the Retail track study allowed Cotton Incorporated to determine four categories of women's clothes where there are opportunities to boost the presence of cotton fiber: dress jeans, outfits, dresses, and knit blouses. Currently, the cotton content in those groups ranges from 30 to almost 50 percent. Kim Kitchings, Senior Director of business Strategy and plan Metrics at Cotton Incorporated, noted that 14 million bales of fibre were consumed in the manufacture of women's wear in 2010. While cotton fiber may be the prominent fibre, various other fibers compete inside key groups identified. In every four groups, large percentages of non-cotton attire are created from synthetic combinations mainly Polyester, Spandex, and Rayon.

The outcomes of the Retail track study allowed Cotton Incorporated to determine four categories of women's clothes where there are opportunities to boost the presence of cotton fiber: dress jeans, outfits, dresses, and knit blouses. Currently, the cotton content in those groups ranges from 30 to almost 50 percent. Kim Kitchings, Senior Director of business Strategy and plan Metrics at Cotton Incorporated, noted that 14 million bales of fibre were consumed in the manufacture of women's wear in 2010. While cotton fiber may be the prominent fibre, various other fibers compete inside key groups identified. In every four groups, large percentages of non-cotton attire are created from synthetic combinations mainly Polyester, Spandex, and Rayon.

To improve the market share for cotton fiber in females's use, Cotton Incorporated is building overall performance technology that'll cause knit garments having drape (how a fabric hangs) and hand (the way in which a fabric seems whenever touched) similar to silk while becoming truly wrinkle-free. Various other factors becoming considered in study stage for the initiative tend to be textile luster and opacity. Bill Rearick, Director of Finishing Research at Cotton Incorporated, noted that the focus on knits is much more useful. "even more cotton goes into knits than wovens in females's use, and knit examples are made here at Cotton Incorporated, " he stated.

Finishing Research is at this time focusing its efforts in performance technology for knits on outfits and skirts two sections in which cotton fiber has got the least expensive share regarding the marketplace. While a long-standing initiative of Cotton Incorporated has been the development of wrinkle weight technologies, Rearick stated the existing focus combines the emphases of both style and science.

New yarn and textile screening gear has become up and running within the item Evaluation Laboratory (PEL) at Cotton Incorporated.

New yarn and textile screening gear has become up and running within the item Evaluation Laboratory (PEL) at Cotton Incorporated.

A fresh Martindale tester, which operates computerized sequences both for textile opposition to scratching and pilling, replaces an identical device. However, the latest machine is bigger than the prior unit utilized in the PEL, enabling as much as nine specimens to be tested at the same time. In both the scratching and pilling tests, three specimens tend to be tested for each textile by ASTM Global requirements.

Into the abrasion resistance test, a fabric test is attached under a weighted control arm and abraded in preset linear and elliptical motions against a wool fabric guaranteed to your flat work surface regarding the circular abrader head. The test is complete as soon as the tester observes a couple of thread breaks on a woven test or a hole in a knitted sample.

The pilling resistance test is comparable to the scratching test, with the exception that the abradant textile is the same as the textile test being tested. The pilling test is made from 100 rounds of preset linear and elliptical movements. The quantity of pilling from the test sample is dependent upon comparison with standard pictures of pilled fabric under managed lighting.

Most of the evaluation carried out because of the PEL regarding Martindale tester is actually for Finishing Research at Cotton Incorporated and is for the intended purpose of evaluating the outcome of abrasion and pilling on examples with varying percentages of applied finishes.

A unique evenness tester, which will be able to supply a count of thick and thin variances and neps in a yarn sample, can also be in use in the PEL. The new tester is automatic to try 1, 000 yards of yarn per package and will test to 24 packages in one run. The majority of assessment conducted by the PEL in the evenness tester is for Fiber Processing at Cotton Incorporated.

A fresh function from the brand-new tester is a textile simulator that displays representations of the way the tested yarn might can be found in various weaves. The latest machine also provides dimensions for diameter, form, and garbage. The details made by the evenness tester is valuable to make yarn selection when it comes to end product. While evenness is desirable in woven textiles for items such as for instance tees, knit tops, and khaki pants, an uneven yarn is appropriate, plus desirable, in woven fabrics for services and products like drapes or the furniture of couches and chairs.

In-house testing at Cotton Incorporated is anticipated to help keep the new testers humming. "ladies' use is an enormous effort right now when it comes to textile researchers, " said Vikki Martin, Director, Quality analysis and item Evaluation. "This task comprises a significant number of our screening for the time being additionally the foreseeable future."

The presence of EFS System computer software has been extended into Vietnam utilizing the present agreement finalized between Cotton Incorporated and Shanghai-based Texhong. Installation may be finished in November 2011.

Mike Watson, Vice President, Fiber Competition at Cotton Incorporated, expressed his understanding for the possibility to increase the relationship with Texhong, whose Chinese operations tend to be present EFS program licensees. Watson noted that Vietnam could very well be the most crucial growing market in Asia. "This arrangement provides Texhong because of the top-quality cotton fiber stock and usage system in the world and can boost their efficiency and profitability in a difficult market, " he stated.