within customer satisfaction studies, Rapanui bamboo clothing consistently score the best approval reviews.

within customer satisfaction studies, Rapanui bamboo clothing consistently score the best approval reviews.

At Rapanui we make use of natural cotton fiber for 80percent of your casualwear and Bamboo as part of the remainder. The possibility for replacing cotton fiber, which makes use of many liquid, is enormous in some means offset because of the intensive handling expected to switch bamboo into a fabric. From an effect perspective, making a decision between which material is way better is a swings-and-roundabouts instance. There are more things to consider, such as the social influence, provenenance, durability, funtion and end-of-life phase for the products. As with every durability, it is not all-black and white.

"Bamboo material is really what is known as a reconstructed or “semi synthetic” fabric . Instead of possessing naturally occurring fibrous consistency that can be spun into threads then product, bamboo is paid down right down to its most rudimentary elements at molecular amount (polymers) after which this goo is shot through a nozzle to help make stringy bits that get spun into a fabric."

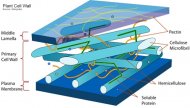

To turn bamboo into textile it really is very first harvested, then leaves and inner pith are broken mechanically. The pieces are wet in an answer (salt hydroxide) for some hours to make them into cellulose that will be among basic foundations of plant life. This occurs in professional facilities in China.

The cellulose is then dried, pushed, crushed and omitted for evaporation to get rid of some of the chemical residue. The remaining is added once again to an answer and forced through a spinnerette, like a shower mind or nozzle. On the other side its rapidly treated to form a material similar to cotton fiber wool which can be woven into a fabric. This procedure happens in a facility with OEKO-TEX (chemi- cal confidence in textiles) standard circumstances in an ISO 14001 factory. The bamboo fibres tend to be incredibly soft, just like silk.

The bamboo fibre will be transported to Asia, to an ethically-accredited factory in which its combined with half the normal commission of qualified natural cotton. It is essential to incorporate cotton fiber for toughness.The facility in Asia is powerered by it’s own devoted wind farm. The completed material is colored, cut and sewn to specification and sent direct towards the British.

This method, where Bamboo is reduced right down to a basic cellulose then reformed is excatly why it's classed as a regenerated fabric and understood sometimes as bamboo viscouse or viscose rayon.

What's so great about Bamboo?

Bamboo flourishes obviously: The yield per hectare is 10 times higher than cotton additionally the feedback of liquid, fertilisers as well as other sources is almost zero. It really is a grass also, therefore it doesn't need replanting, that will help reduce topsoil erosion. It grows up to a yard per day in places, effortlessly pulling in sunshine and greenhouse gases and changing it into biomass. Therefore, Bamboo features lots of potential for sustainability.

No to harmful chemicals.

Our bamboo items come with Oeko-Tex 100 official certification. This helps ensure that this phase associated with the supply chain is comprehensively and responsibly looked after - you can find no harmful chemical substances in finished item and no harmful chemicals moved in to the making of the item.